CNC turning and CNC engraving

Today, industries are deeply interconnected. In the way that we see the use of some practical tools simultaneously in several industries. CNC lathe is one of these practical tools that are used in many production processes. In fact, the performance of CNC lathe is completely equal to the performance of master artists. The only major difference is that in this method, the final accuracy of the work is increased with precise and complex calculations.

CNC lathe has greatly improved due to the presence of artificial intelligence and new technologies. For this purpose, we see the use of CNC turning on hard and impermeable materials such as natural stone. Today, CNC turning and CNC engraving is one of the significant activities in the production of stone products. Users produce special and special products in this industry with the help of knowledge and art.

Introducing the turning and cutting process with CNC and industrial waterjet machines

The advanced CNC machine has made stone cutting very easy for manufacturers. The CNC machine has easy and very precise management and adjustment. The many advantages of using CNC lathe and CNC milling have caused it to quickly replace the traditional method and old devices. Of course, it should be remembered that the use of these specialized tools requires sufficient knowledge and experience.

The user first designs the desired design manually. Finally, he uploads the design in the control section of the CNC machine. The use of the new CNC lathe method has caused the performance of users to increase greatly. This has caused the amount of executive and administrative burden of users to be reduced at the same time. Generally, the working method of all CNC machines is not the same and the working method also changes based on the type of function.

Investigating the benefits of using CNC lathes and CNC lathes

The first advantage that can be mentioned for CNC lathes and CNC milling machines is the continuous and continuous operation of these tools. Working with these devices is relatively easier than other stone cutting and turning methods. CNC machines can be easily updated with a few hardware changes. Also, working with these devices is much easier than traditional methods. In terms of cost, performing CNC turning and CNC milling process with these devices brings lower costs for users. Stone cnc machines are usually used for many things. For example, this practical tool is mainly used to create beautiful designs on the facade of the building, to produce precise and beautiful tools such as stone columns and fences, sculpting and carving, and also to create beautiful and eye-catching designs on the interior and exterior of structures. they say

To know the method of applying the marble on the natural stone

Maraq has been one of the oldest industries in Iran, which has been transformed over many years. The master works by using geometric shapes, designs inspired by nature to create beautiful and unique works. CNC engraving is one of the new methods of creating beautiful designs on natural stone. Big manufacturers such as Ara Stone have been able to use new methods and practical tools. To produce unique products in the field of stone carving and cutting.

Ara Stone Company is able to implement beautiful designs on building facade components, tools produced by this company, and even on artifacts produced from natural stone. The company’s experts can create beautiful designs from the CNC machine on natural stone profiles and cornices, mantelpieces, stair boxes and staircases, natural stone countertops and islands, stone sinks, and many tools made of natural stone. All stages of production, preparation, manufacturing and assembly, turning, installation, design, lighting, corner drawing, strengthening of these products are done in Ara Stone.

By using advanced tools in the field of implementation, Ara Stone Group has the ability to perform all kinds of installation items, and with a staff of about 100 fully specialized and committed people, it has the ability to install in various fields. For each project, Ara Stone Company employs an experienced and experienced supervisor to supervise the installation matters and is fully coordinated with the client and the designer, which is important to create coordination and progress as much as possible in the various stages of implementation.

The most important difference in the Ara Stone collection, which can be considered a parent company or a large holding company in the field of stone, because the ability (production, procurement, construction and assembly, cutting, installation, design, lighting, cornering, retrofitting and many other services) ) which is not included in this chapter, and different companies and organizations, as well as our dear colleagues, designers and custom builders, can cooperate with our collection without any worries in the field of stone.

Certainly, the effort of Arastone Group and the true belief of this large group at the level of the country and abroad is to prefer the continuity of cooperation and the favorable satisfaction of cooperation to the quantity in the discussion of order registration. This win-win event between Ara Stone Collection and all the people who intend to cooperate with us is a guarantee of choice and priority in choosing Ara Stone Collection. A strong resume in the field (workshop, factory, execution, design group) is another honor of this collection.

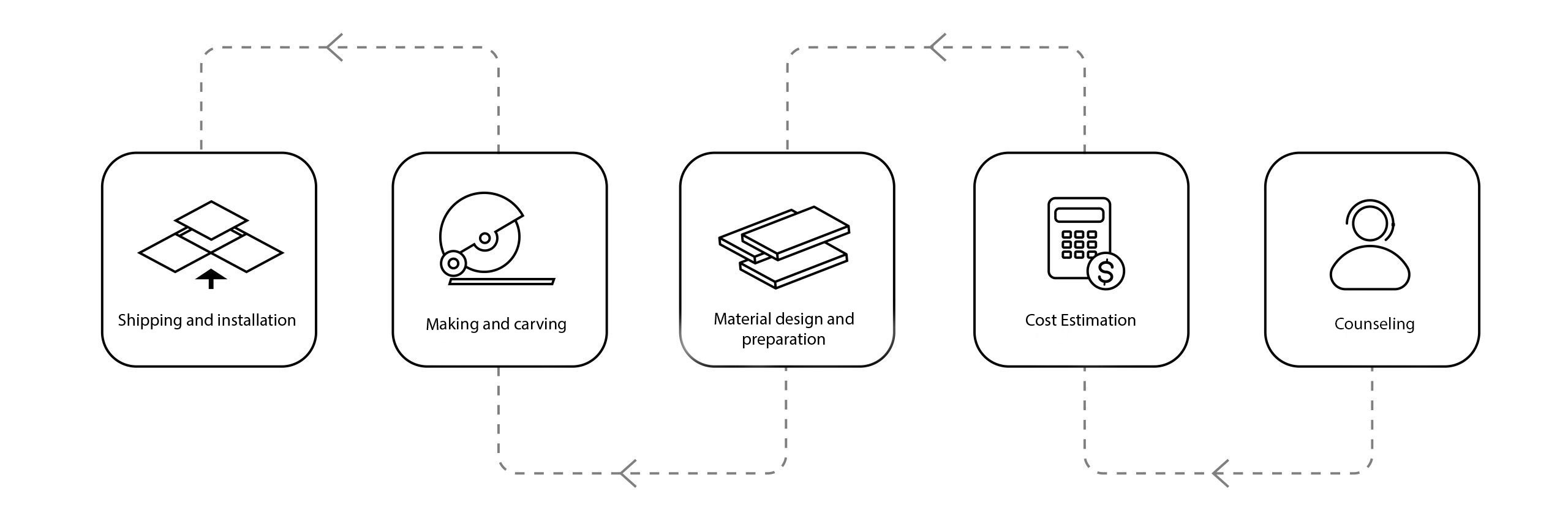

Work steps

CNC stone and marble CNC turning services, CNC water jet cutting

- Turning all kinds of facade components with the most advanced CNC machines (in sync with the latest facilities in the world)

- CNC waterjet and CNC cutting

- CNC lathe in different dimensions and parts

- Ligament cutting in different axes

- Production of all kinds of headstones, pastons, statues, Sardis and stone sculptures

- Mixed assembly of stone with stone and tile or ceramic

- Fragile assembly in the smallest strap and the distance between components up to one millimeter

- Installation and execution of all kinds of classical, modern, neoclassical facades

- Implementation of different types of dry slabs in different dimensions

- Implementation of dry slab pinning on the surface of the facade

- Strengthening and substructure of dry slabs on the facade

- Implementation of mortar and adhesive slabs on the floor and body in different dimensions

- Farsibar cutting and all kinds of tools at different levels

- Integrated strengthening of all types of tiles and slabs for dry execution

- Production of all kinds of CNC wave partitions (completely exclusive)

- Preparation of stone, sending factory turning tools, installation and final

- Designing all kinds of proposed designs in a completely professional way (fully specialized designer staff)

- Registering and sending orders all over Iran and abroad

- Production of various surface profile files

- Production of all kinds of classic cornices

- Preparation of all kinds of coupes and thick ingots (the best available coupes)

- Production of all kinds of home decorations

- Implementation of backlight of all types of body slabs and marble floor

- Surface lighting and all types of slabs and hidden lighting (completely professional)

- Structural drawing and corner drawing of facade surface or different bodies for stone installation (tile or thick ingot or slab)