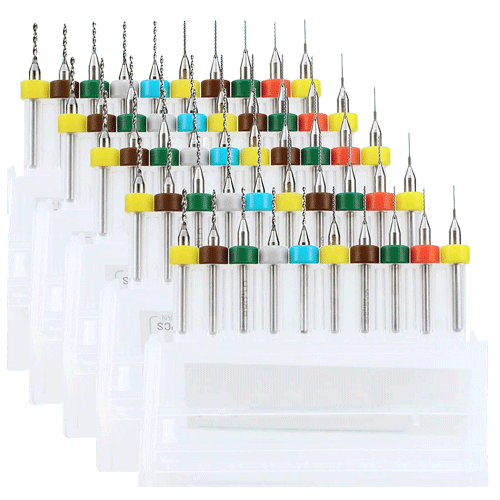

CNC cutting drill

A CNC cutting drill is a cutting tool used by CNC (Computer Numerical Control) machines. CNC is an advanced production technology that performs cutting operations with high accuracy and repeatability through computers and appropriate software.S

CNC cutting drill has a different structure than traditional drills. This type of drill is designed with high precision and faster cutting speed and is used for cutting and drilling holes in various materials such as metals, wood, plastic and composite materials.

A CNC cutting drill generally has a cylindrical shank that can be adjusted to different designs and dimensions. Also, the drill head (tip) is also selected to match the type of material of the part and the operation required.

The advantages of using a CNC cutting drill include high precision, fast performance, repeatability, the ability to cut complex designs, and advanced programming features. With the use of CNC cutting drill, it can be effectively used in various industries such as machinery industry, automobile industry, electronic industry, and wood and furniture industry.

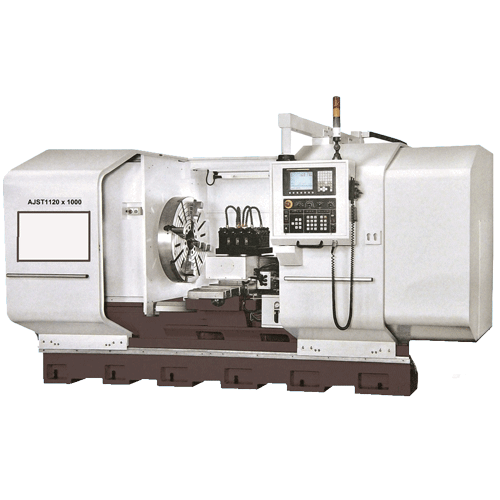

CNC lathe

Nowadays, some CNC lathes are widely used for turning various surfaces such as the sides of building stones. These tools are among the most widely used tools that are used for CNC cutting drill and CNC turning of different materials. Therefore, in the following, we refer to the types of CNC cutting and turning drills that are specifically mentioned in the construction industry.

For turning and drilling stones such as ceramics and tiles, they use one of the most durable CNC lathes, called diamond drills. These drills are made of carbide steel and are divided into two groups of two-diamond and four-diamond drills. This month is one of the important months for people active in the field of construction. Of course, diamond drills are divided into types of round bottom, four grooves and five grooves in terms of the shape of the end part. Four-slot drills are widely used for drilling building stones; Because it simplifies the cutting work and increases the work speed. The second category of drills used for building stones is the granite drill. Although its appearance is similar to a diamond drill and it is durable like that; But it is specially used for drilling granite stones and similar stones. When using a granite drill, water should be used to reduce the negative effect of heat.

CNC cutting drill price

The price of CNC cutting drills may depend on several factors. In the following, I will discuss some of these factors and how they affect the price of CNC cutting drills.

- Drill Size: The diameter and length of the CNC cutting drill bit can affect the price. Larger and longer drills may cost more.

- Body Material: CNC cutting drills are usually made of ceramic steel, carbide, or diac to increase wear and heat resistance. The material of the drill body can also have a great effect on the price. Carbide body drills are usually more expensive than other types.

- Cover type: Some CNC cutting drills are coated with coatings such as titanium nitride (TiN), titanium carbide (TiC) and altin (AlTiN). These coatings help the drills to be more resistant to wear and heat. Drills with advanced coatings usually cost more.

- Producer: CNC cutting drills are made by different companies and each company may set its price based on different factors such as quality, technology and reputation. Famous and trusted brands may cost more.

- Number of videos: CNC cutting drills usually have several blades that are used to cut different materials. Drills with a higher number of vidya usually cost more.

Therefore, the price of CNC cutting drills depends on factors such as size, body material, coating type, manufacturer and number of blades. To know the exact price of CNC cutting drills, it is better to contact the suppliers and manufacturers of the drills because the prices may vary at different times and places.

CNC lathe price

The price of CNC lathe depends on several factors. The price of CNC lathe depends on several factors.

- Size and complexity of the piece: The size and complexity of the part to be produced by the CNC lathe will affect the price of the lathe. Larger and more complex parts cost more due to the need for more planning and time.

- Material: The type of material that is going to be turned plays an important role in the price of CNC turning. Harder and more resistant materials usually cost the most to turn.

- Number of lathe operations: If the part requires a large number of turning operations, more time and cost will be required to produce it. Typically, each additional turning operation incurs additional costs.

- Programming complexity: Detailed and complex programming for a CNC lathe can require more time and effort. The complexity of programming usually adds to the price of the lathe.

- Machine technology and precision: CNC lathes with advanced technology and high precision usually have a higher price. The use of advanced equipment can increase the cost of CNC turning.

- Accessories: Some CNC lathes require additional equipment such as turning tools, cooling system, chip collection system, etc. These accessories may increase the cost of the lathe.

- Geographical location: The price of CNC lathe may vary in different regions or different countries according to labor costs, raw materials and equipment.

In general, to know the exact price of CNC lathe, it is better to contact workshops and manufacturers Arastone Manufacturer of CNC cutting drills and CNC lathes. You can consult and receive services with Ara Stone Company Get in touch and provide them with the details of your project so they can provide you with an accurate price estimate. Also, you can choose the best price by comparing different offers and prices from several sources.